PRODUCT CENTER

Medical Oxygen Generation System

Features:

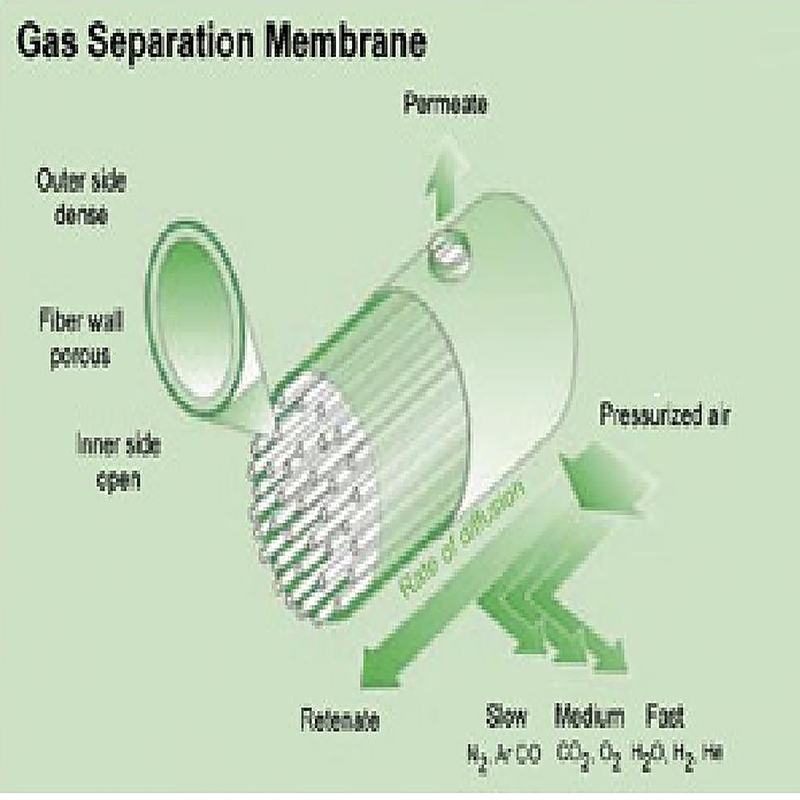

The pressure swing adsorption (PSA) oxygen generation systems designed for hospital applications leverage PSA technology to facilitate the physical separation of oxygen from atmospheric air, eliminating the need for chemical reactions to produce multiple gases.

These systems capitalize on the unique properties of zeolite molecular sieves, which selectively adsorb nitrogen, carbon dioxide, carbon monoxide, and other gaseous components, while allowing oxygen to pass through the sieve bed.

Through this adsorptive process, purified oxygen is recovered, while the adsorbed gas components are vented to the atmosphere.

The oxygen gas produced by these PSA generation units meets the stringent purity requirements outlined in the United States Pharmacopoeia (U.S.P) XXI Oxygen 93% Monograph.

Product Details

The pressure swing adsorption (PSA) oxygen generation systems designed for hospital applications leverage adsorption technology to facilitate the physical separation of oxygen from air, circumventing the need for chemical processes to produce multiple gas streams. These units exploit the selective adsorption properties of zeolite molecular sieves, which trap nitrogen, carbon dioxide, carbon monoxide, and other gaseous components, while allowing the oxygen to pass through the sieve bed. This process enables the recovery of purified oxygen, while the adsorbed gas components are vented to the atmosphere. The oxygen gas produced meets the stringent purity criteria outlined in the United States Pharmacopoeia (U.S.P) XXI Oxygen 93% Monograph.

These on-site oxygen generation plants are gaining increasing popularity in hospitals worldwide due to their unique advantages over traditional oxygen cylinders and liquid bulk oxygen systems. Key benefits include:

-Cost-effectiveness: With a low energy consumption of only 1.5kWh/m3, these systems offer significant cost savings compared to cylinders or liquid dewars.

-Enhanced safety: Operating under low-pressure and ambient temperature conditions.

-Convenience: Eliminating the need for procurement, transportation, storage, and managing boil-off losses associated with traditional oxygen supply methods.

-Energy efficiency and environmental sustainability: No chemical materials are required, and the only consumable is electricity, resulting in a pollution-free operation. Automated control and monitoring systems ensure efficient and reliable operation.

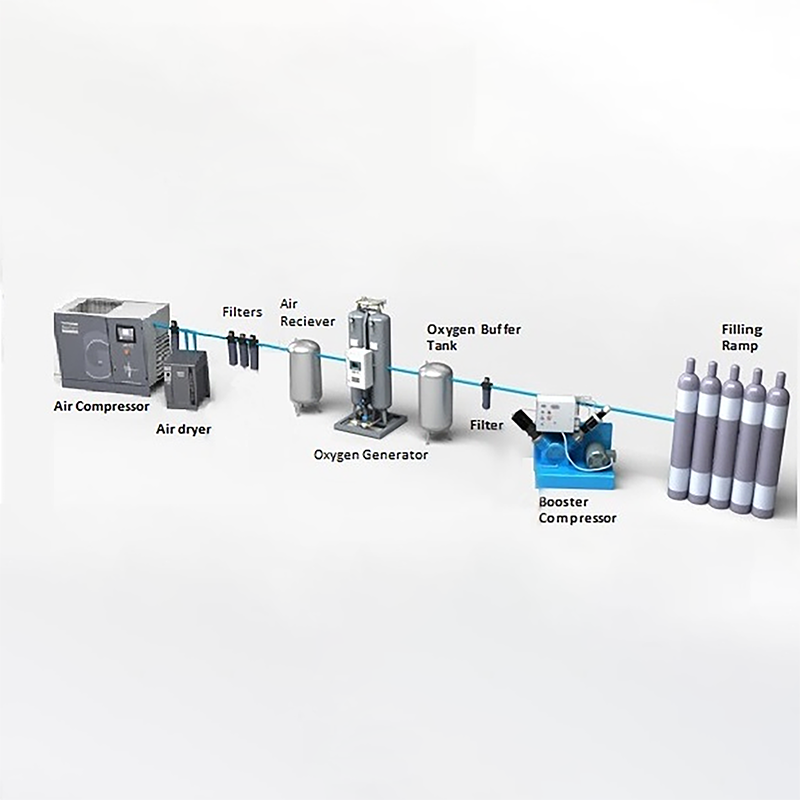

These comprehensive oxygen production plants incorporate components such as air compressors, air dryers, multi-stage filtration systems, receiver tanks, instrumentation and sensors, cloud-based monitoring systems, and electrical control systems.

Features of medical oxygen production system:

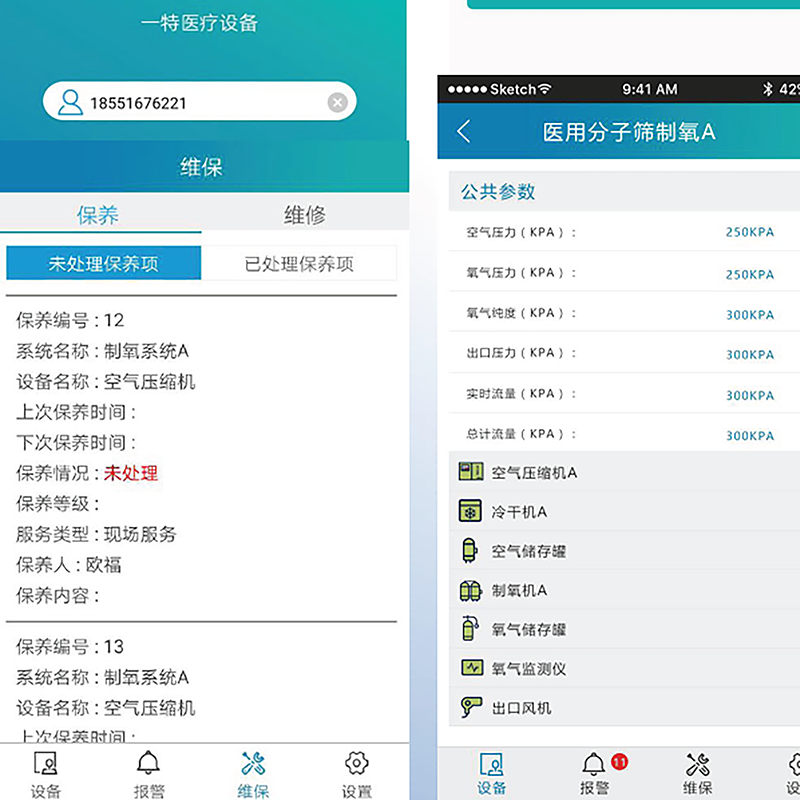

• The system offers both automated and manual operation modes.

• User-friendly and straightforward operation, with mouse-click simplicity for executing commands.

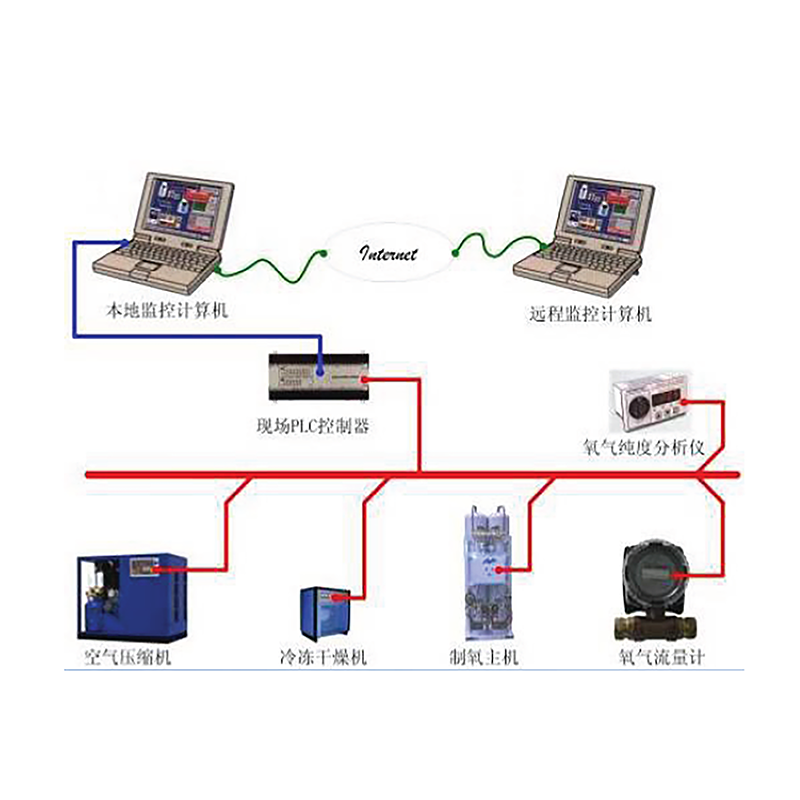

• Real-time monitoring of operational status, with alert and alarm notifications for any detected faults or anomalies.

• During normal oxygen demand scenarios, a single oxygen generation line automatically initiates to meet the hospital’s requirements. An automatic switching mechanism between multiple lines ensures optimal energy efficiency.

• In the event of maintenance or repair requirements for a single component, standby units can be automatically activated to ensure uninterrupted operation.

• The manifold oxygen supply can seamlessly switch to an alternate source in the case of power failures.

• Integrated high-precision oxygen purity and flow monitoring devices enable real-time tracking of output parameters, ensuring the produced oxygen meets quality standards.

• A redundant configuration comprising the oxygen production system and a standby manifold station guarantees an uninterrupted oxygen supply.

• Remote monitoring and control capabilities allow the supplier’s central control facility to monitor the operating conditions of each installed unit, providing timely recommendations and support. This remote access also enables prompt detection and troubleshooting of breakdown alerts.