High Reliability, High Performance, Low Operating Costs Perfect Field Gas Solution

PSA means Pressure Swing Adsorption. This On Site PSA nitrogen generator is based on following working principle. Compressed air through filtration and purification to remove remnant water, oil, dust, and then enters adsorption vessel filled with molecular Sieve. Oxygen is absorbed by sieve and desired nitrogen passes to output as product as .

Cryogenic oxygen plant ASU can generate only oxygen, or generate both oxygen and nitrogen in gas or liquid form. The working principle of it is that dry saturated air with purifications to remove moisture, impurities entering the lower tower becomes liquid air as it continues to be cryogenic. Physically air is separated, and high purities oxygen and nitrogen are obtained by rectifying in fractionating column according to different boiling points of them.

PSA means Pressure Swing Adsorption. This On Site PSA oxygen gas generator is based on following working principle. Compressed air through filtration and purification to remove remnant water, oil, dust, and then enters adsorption vessel filled with molecular Sieve. Nitrogen is absorbed by sieve and desired oxygen passes to output as product gas at purity 93+/-3% (90%-96%), specially 99.5% purity oxygen is available with a purifier.

Medical Oxygen Generation System

The PSA oxygen generation plant for hospital is based on PSA technology to physically separate oxygen from air, meaning there is multi gases made from chemical reaction. It utilizes the characteristics of zeolite molecular sieve to absorb nitrogen, carbon dioxide, monoxide and other gases but releasing oxygen out of sieve. In this way oxygen is acquired while other gases are ventilated to atmosphere. The produced oxygen gas meets the United States Pharmacopoeia (U.S.P) XXI Oxygen 93% Monograph.

Central Vacuum Aspiration System

Central vacuum aspiration system is generally used eliminate liquid of patients, such liquid in body, cleaning intestines and stomach, dirt of chests and lungs, absorb phlegm etc.

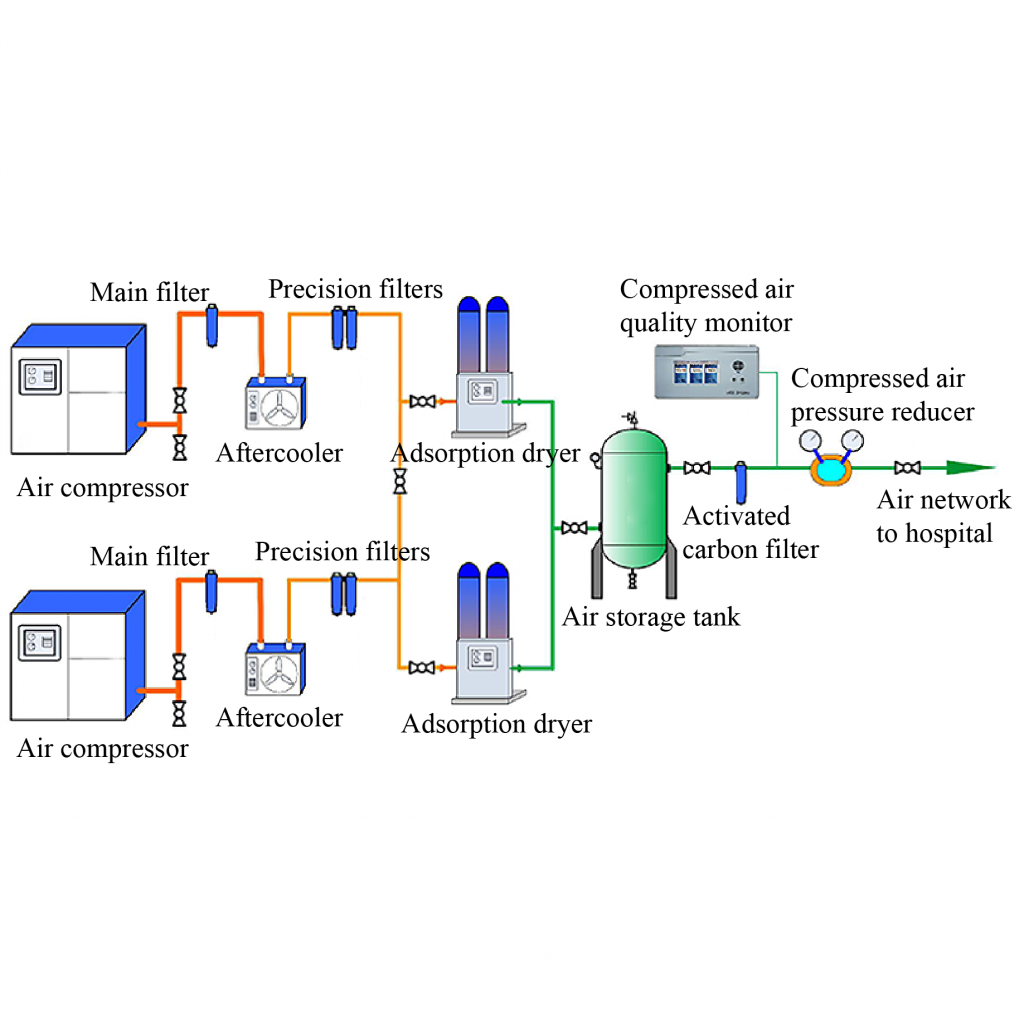

Compressed Air System

The medical compressed air system for hospital is always used patients inhaling, mixed as anesthetic gas, infant care, power gas for surgery tools etc. It is essential to use clean dry oil-free compressed air to meet food grade.

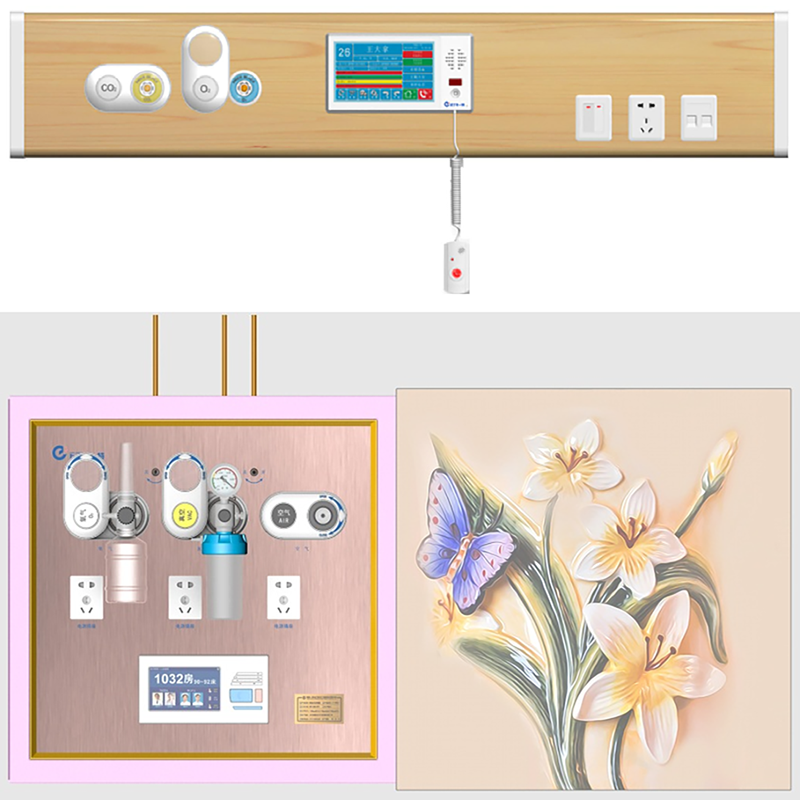

Central Gas Supply Pipe Network System & Ancillary System

It is the channels to distribute produced gases to terminals in related rooms. It consists of medical gas pipe network system (oxygen pipeline system, compressed air pipeline system, vacuum suction pipeline system), bed head unit system, Internet of Things mobile nursing system etc.

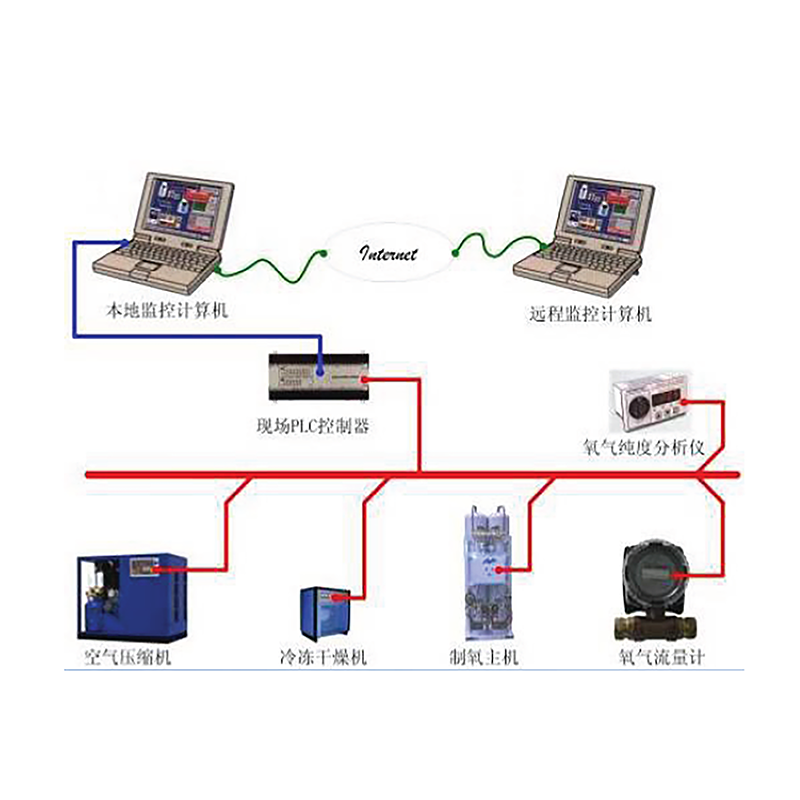

Gas Cloud Platform Monitoring & Alarm System

The gas monitoring & alarm management system is an integration of monitoring running parameters, maintenance reminders and trouble-shooting records, alarms reminders, parameters settings.

Engineering Of Central Gas Supply Work

Medical gas supply engineering system is an integration of equipment and engineering work. Equipment & devices include oxygen generator, reserve oxygen by manifold, reserve liquid oxygen, vacuum plant, compressed air plant, together with pipeline network system, nurse call system, bed head unit system etc.