PRODUCT CENTER

Medical Cleansing Engineering

Features:

Medical cleansing engineering refers to the process of creating and maintaining sanitized environments that adhere to healthcare facility standards and regulations. The focus areas span various clinical spaces and diagnostic testing sites requiring stringent hygiene controls.

Key areas subject to these stringent cleansing protocols include operating suites, labor and delivery rooms, intensive care units (ICUs) for adult, pediatric and neonatal patients, cardiac care units (CCUs), interventional therapy rooms, clinical laboratories, pathology departments, and blood transfusion service areas.

Product Details

Medical cleansing engineering refers to the specialized discipline of creating and maintaining sanitized environments within healthcare facilities to meet rigorous standards and regulations. The focus areas span clinical spaces and diagnostic testing sites that demand stringent contamination control measures.

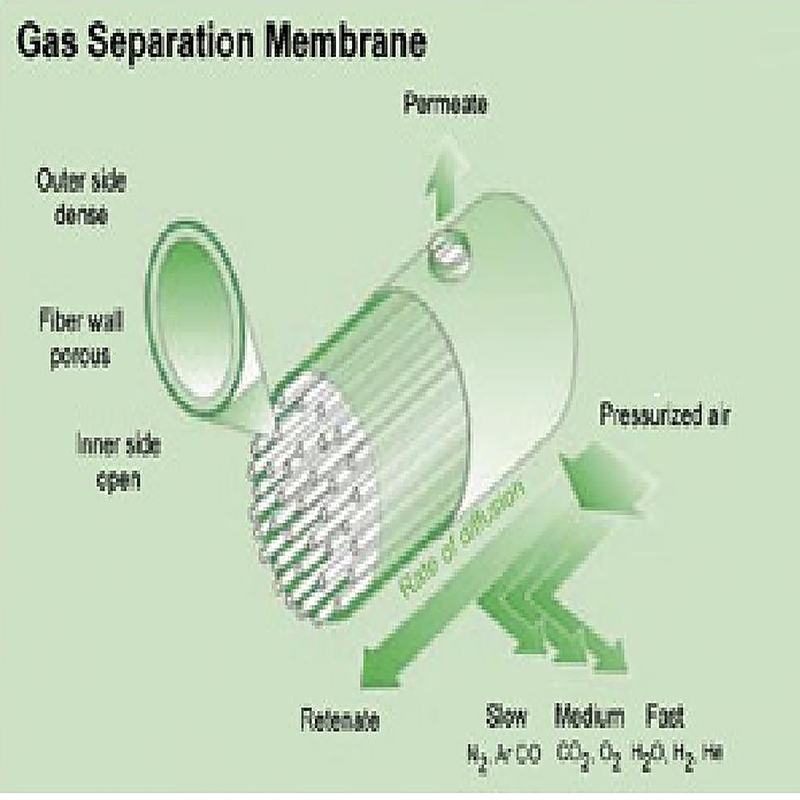

Cleanrooms are a critical component, utilizing advanced engineering controls to remove microscopic particulates, harmful gases, microbes, and other contaminants from the air. These environments maintain tightly regulated parameters for temperature, air cleanliness levels, pressurization, airflow patterns, noise/vibration, lighting, and static electricity discharge – ensuring stable, aseptic conditions regardless of external factors.

There are four classified cleanliness levels based on allowable airborne and surface particulate limits. The most stringent Level 1 is for operating rooms, while labor/delivery and intensive care units fall under Level 2.

Implementing these controlled environments is a multidisciplinary effort spanning architectural design, HVAC systems, electrical work, medical gas distribution, and more. Each discipline adheres to exacting codes and best practices – for instance, interior finishes must meet fire/smoke ratings, minimize particle shedding, resist microbial growth, and provide durable, easy-to-clean surfaces.