PRODUCT CENTER

Hydrogen Purification Unit

Features:

Our gas separation and purification solutions for hydrogen purification units seamlessly integrate pressure swing adsorption (PSA), cryogenic separation, and chemical absorption methodologies. This multi-faceted approach enables us to tailor our offerings to diverse gas feedstock compositions and desired product specifications, ensuring we provide our clients with optimized solutions.

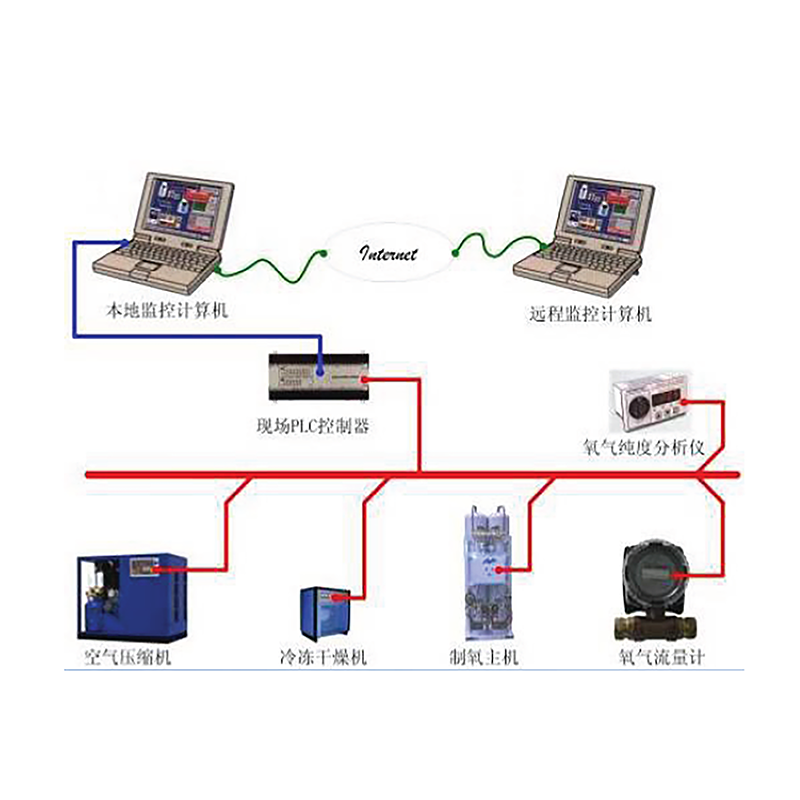

We employ advanced adsorbents of the highest quality, including specialized hydrogen and carbon monoxide adsorbents, renowned for their exceptional adsorption capacities, selectivity, mechanical robustness, and prolonged service lives – positioning our technology at the forefront of global standards. Our hydrogen recovery plants are equipped with intelligent control systems, facilitating functions such as automatic pressure regulation, fault self-diagnostics, automatic parameter optimization, and system safety interlocks.

Key features of our solutions include:

1) Highly automated operation, enabling unmanned on-site management.

2) Capability for stable, continuous operation throughout the year without interruption.

3) Compact arrangements and reduced installation footprint.

4) Adjustable flow rates ranging from 30% to 100% of capacity.

Product Details

Purification installations are employed to enhance the hydrogen concentration in industrial gas streams with relatively low hydrogen purity levels. This enrichment process aims to meet the stringent purity requirements mandated by various commercial applications.

Accepted feed sources: Shift gas streams, dry gas mixtures, coal-derived gaseous products, residual gases from methanol product processes, reformed hydrogen gas streams, among other hydrogen-rich gaseous feedstocks.

Process:

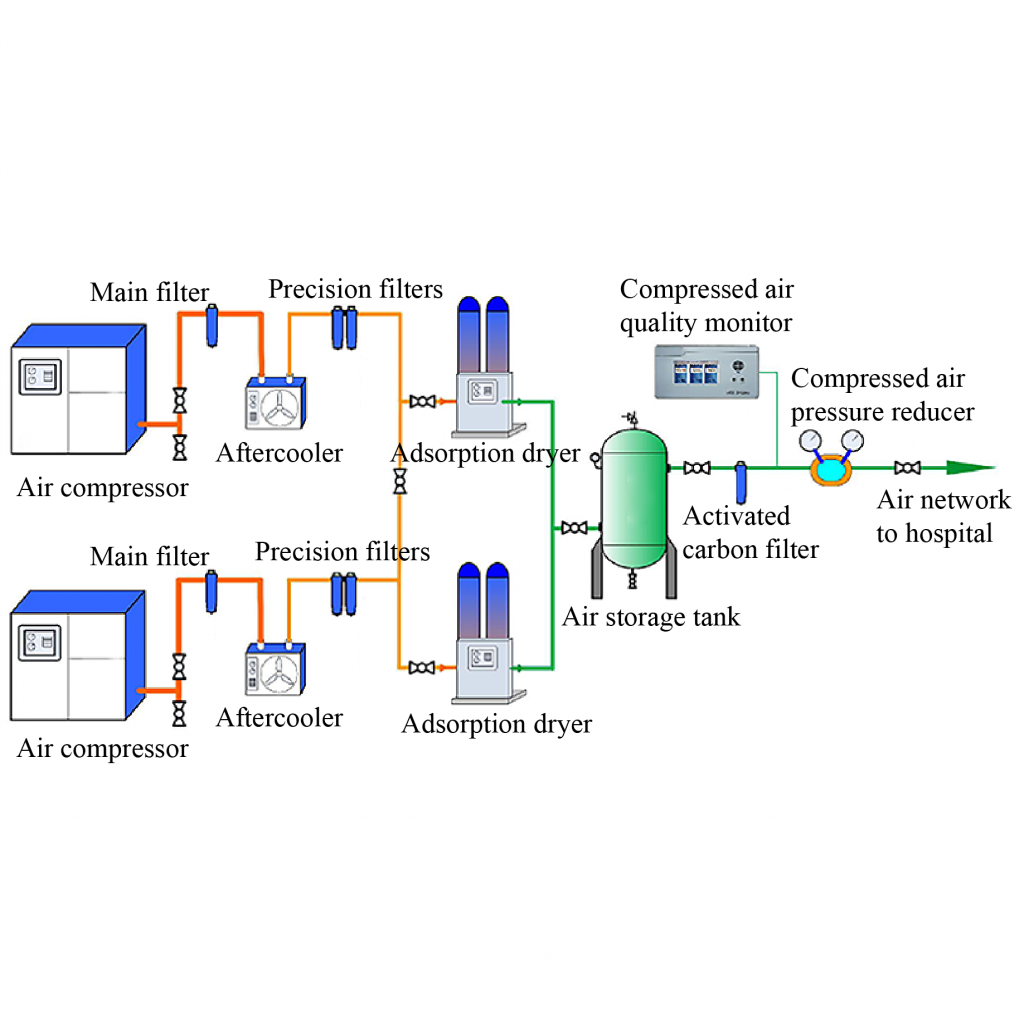

After passing through the buffer tank, the feed gas proceeds into the pressure swing adsorption (PSA) towers laden with adsorbent materials.Within these towers, a sequence of physical processes, including adsorption, pressure equalization, desorption via reverse flow, and vacuum regeneration, takes place. This series of steps allows the adsorption towers to complete a full “adsorption-regeneration” cycle. Through this cyclic process, the purification of the hydrogen-rich stream is accomplished, thereby achieving the objective of hydrogen recycling and recovery.

| Capacity | 10-400,000Nm3/h |

| Purity | 99%-99.9995% |

| Pressure | 0.4-5.0MPa(G) |