PRODUCT CENTER

Gas Drying Unit

Features:

1) The specially engineered program-controlled valves demonstrate exceptional reliability, with a mean time between failures exceeding 20 years (excluding seals).

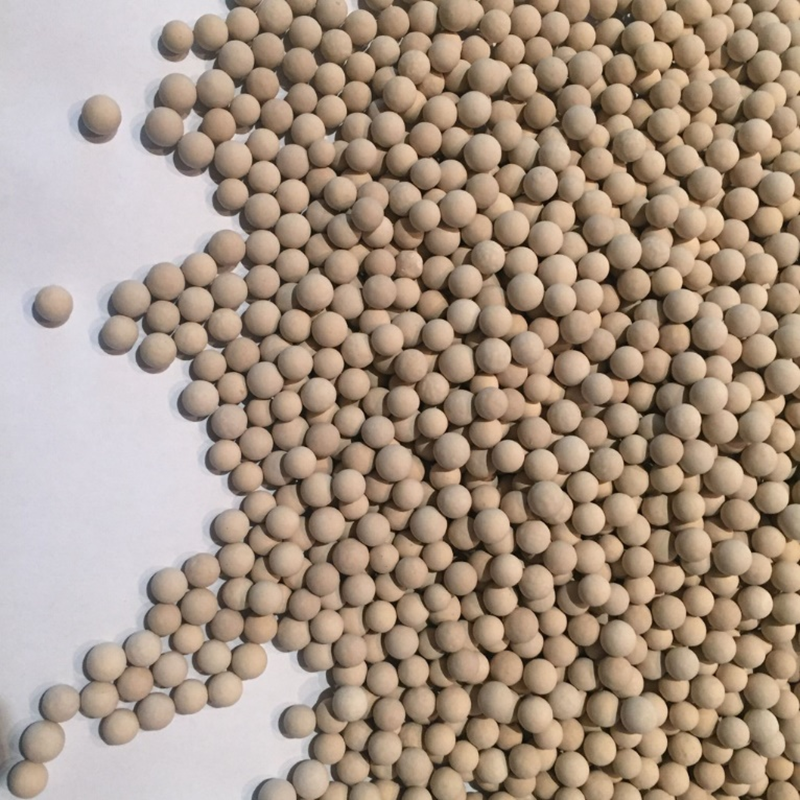

2) The desiccant material employed offers an extended service life of over 3 years before requiring replacement.

3) A proprietary patented desiccant formulation provides superior adsorption capabilities and enhanced performance characteristics.

4) The optimized design results in a low average drying cost per unit volume of gas processed.

Product Details

Feed gas: natural gas, hydrogen, CO2 etc.

Product gas: H2O <0.1ppm

Process:

The drying system comprises two adsorber vessels working in parallel, along with auxiliary equipment like a heater for regeneration gas, a regeneration gas cooler, and a water separator. While one adsorber is in the drying service mode, the other is undergoing regeneration of the desiccant bed. Each adsorber cyclically rotates through the following stages: adsorption to remove moisture, depressurization, heating to desorb accumulated moisture, and repressurization. An automated valve sequencing system orchestrates the transition between these steps in the cycle. The two adsorbers operate in a staggered cycle, with one always in the drying mode while the other regenerates. This counter-current swing adsorption allows for continuous production of dry gas.