High Reliability, High Performance, Low Operating Costs Perfect Field Gas Solution

PSA means Pressure Swing Adsorption. This On Site PSA nitrogen generator is based on following working principle. Compressed air through filtration and purification to remove remnant water, oil, dust, and then enters adsorption vessel filled with molecular Sieve. Oxygen is absorbed by sieve and desired nitrogen passes to output as product as .

Cryogenic oxygen plant ASU can generate only oxygen, or generate both oxygen and nitrogen in gas or liquid form. The working principle of it is that dry saturated air with purifications to remove moisture, impurities entering the lower tower becomes liquid air as it continues to be cryogenic. Physically air is separated, and high purities oxygen and nitrogen are obtained by rectifying in fractionating column according to different boiling points of them.

PSA means Pressure Swing Adsorption. This On Site PSA oxygen gas generator is based on following working principle. Compressed air through filtration and purification to remove remnant water, oil, dust, and then enters adsorption vessel filled with molecular Sieve. Nitrogen is absorbed by sieve and desired oxygen passes to output as product gas at purity 93+/-3% (90%-96%), specially 99.5% purity oxygen is available with a purifier.

PSA oxygen generators

PSA means Pressure Swing Adsorption. This On Site PSA oxygen gas generator is based on following working principle. Compressed air through filtration and purification to remove remnant water, oil, dust, and then enters adsorption vessel filled with molecular Sieve. Nitrogen is absorbed by sieve and desired oxygen passes to output as product gas at purity 93+/-3% (90%-96%), specially 99.5% purity oxygen is available with a purifier.

VPSA Oxygen Plants

VPSA means Vacuum Pressure Swing Adsorption. Feed air is sucked filters for removal of dust before boosted to 0.3~0.5barg by roots blower. It then goes into an absorber full of absorbent activated aluminum to eliminate water, CO2 and other gases at the bottom, above which N2 absorbed by absorbent zeolite molecular sieve. O2 with argon is output on the top as product gas into oxygen buffer tank and then boosted to higher pressure by oxygen compressor to consumption point.

Cryogenic O2/N2/Ar plants

Cryogenic oxygen plant ASU can generate only oxygen, or generate both oxygen and nitrogen in gas or liquid form. The working principle of it is that dry saturated air with purifications to remove moisture, impurities entering the lower tower becomes liquid air as it continues to be cryogenic. Physically air is separated, and high purities oxygen and nitrogen are obtained by rectifying in fractionating column according to different boiling points of them.

PSA N2 Generators

PSA means Pressure Swing Adsorption. This On Site PSA nitrogen generator is based on following working principle. Compressed air through filtration and purification to remove remnant water, oil, dust, and then enters adsorption vessel filled with molecular Sieve. Oxygen is absorbed by sieve and desired nitrogen passes to output as product as .

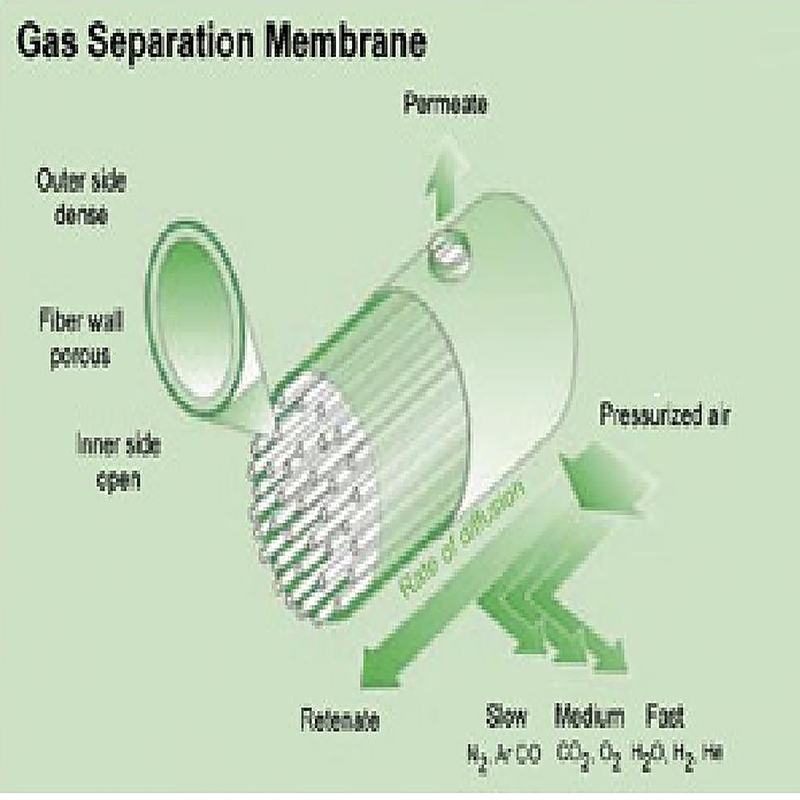

Membrane N2 Generators

Due to permeability differences of each gas, when compressed air goes through the membrane units, oxygen passes through membrane walls to atmosphere, while nitrogen is collected at outlet as a product gas. Higher pressure leads to higher permeability of each gas.

Liquid N2 Generator

On site liquid nitrogen generation plant makes it possible for customers not to purchase liquid nitrogen LN2,and saves troubles of its transport, evaporation loss, carrying dangers etc.