First, use requirements

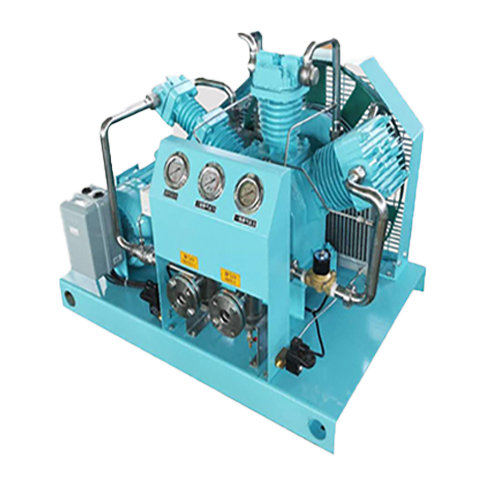

1). Oxygen compressor need normal operation according to user manual requirements.

2). Oxygen compressor operator needs training and understanding its use and security matters.

3). A designated staff needed is responsible for the oxygen compressor’s maintenance and overhaul.

4). When oxygen compressor comes into normal use, pay attention to security protection and prevent high-temperature, high pressure, current causing personal injury.

5). When oxygen compressor is on, it is strictly forbidden to tighten up pipeline or compression cylinder bolts.

6). It is permitted that customer deal with the failure according to safe operation requirements.

7). If customer can not deal with the failure, make a record for failure phenomena; promptly notify supplier to solve it.

8). Any processing that can’t satisfy safe-operation requirements is strictly prohibited.

Second, safe running of oxygen compressor

When oxygen compressor normally runs, there is uniform airflow sound; compressor and machine run without noise and vibration. If the oxygen compressor sound is mussy, noisy and vibrational, it is abnormal. If any following phenomena occur, please shut down and repair compressor immediately.

1) The bearing temperature continues to rise and exceed the normal level;

2) Noise, vibration, booster engine whistles;

3) The outlet gas temperatures are high, inter-stage cooler leak water and gas;

4) Volume of pumping gas decreases, and sometimes appears asthma and shake.

The operator on duty pays attention to the oxygen compressor inspection work, inspect items as follows:

1)Check whether voice is normal without noise when each part of oxygen compressor during is running;

2) Check whether the lubricant oil pressure, temperature, oil level is normal;

3) Check whether cooling water temperature on inlet and outlet is normal;

4) Check whether inter-stages cooler leaks water or gas on oxygen compressor;

5) Check whether Oxygen compressor bearing temperature is normal;

6) Check whether oxygen compressor and booster engine leak oil or gas;

7) Check whether the axial displacement and radial overtake limit for oxygen compressor.

If the above-mentioned phenomena occur, please promptly report as soon as possible.

Three, maintenance and overhaul

1). In accordance with operating instructions of compressed oxygen, carry out maintenance, repair, regular inspection and replacement of lubricants, valves, diaphragm and other wearing parts.

2). During maintenance and repair, oxygen compressor must get rid of water, power and keep non-working state. As occasion requires, connect to cooling water or electricity.

3). Maintenance and repair, to ensure Booster completely uninstall the compression level to ensure that all parts are in high-temperature room temperature.

4). According relevant requirements, replace lubricants, valves, diaphragm; we need prevent unnecessary damage, ensure parts cleanliness and prevent pollution of membrane cavity.

5). While maintenance and repair is completed, check whether various valves and instrument is installed correctly.

6). Any modification which are related to high-pressure pipeline, need processing by specialized maintainer, and then carry out pressure and gas tightness test .

Attachment: the specific process of maintenance & overhaul.

1). preparation before oxygen compressor maintenance operations

Maintenance projects ought to set down maintenance plan and strict security measures. Special appointed person ought to be responsible for each maintenance project. Before perform maintenance operations, fill out various safe ticket and certificate strict according to criterions and regulations. According to maintenance project, content and requirements, prepare the required materials, spare parts and tools. Do a good inspection for lifting equipment. When service people get into work site, ought to wear individual labor protection uniform.

2). the overhaul of main frame: Disassemble various components and place them reasonably. If part is of seal face, please operate carefully to avoid bumps. Clean components, replacement spare parts (e.g. labyrinth sealing device, O-ring, etc). Then assemble components which contacts with oxygen, please carry out degreasing cleaning to eliminate grease, and avoid creating foreign matter or falling into the cylinder. At all levels, adjust the bearing clearance at all levels carefully; make sure shaft coupling installation dimension is high precision. Otherwise it would cause large vibration, bearing damage and the diaphragm rupture of diaphragm-type coupling. At the same time make a good record of various data for archiving.

3). auxiliary frame maintenance: clean dirt for cooler shell, improve heat-exchange effect, and make sure pipeline oil-free, no impurities. Focus on clean-up of oxygen filter, if there are holes, please replace in time. Make sure lubricating oil system is no leakage and oil level is normal.

4). the acceptance after equipment maintenance

When maintenance is complete, please check whether miss any maintenance projects. Count tools, equipment, remove all kinds of garbage, and make sure a variety of safety devices work normally. After general examination, test oxygen compressors, including the pressure test, leak testing, test instrumentation sensitivity and test interlocking devices. If all are qualified, please put into use.