Zeolite molecular sieve is a kind of crystalline microporous material consisting of silicon-oxygen tetrahedron and aluminum-oxygen tetrahedron connected to each other through shared oxygen atoms and has uniform intracrystalline pores. Generally, natural and synthetic zeolite zeolite refers to aluminosilicates.

Zeolite molecular sieve can not only be used in catalysis, adsorption, separation and other processes, but also can be used in emerging fields such as microlasers, nonlinear optical materials and nanodevices, and has broad application prospects in the fields of medicinal chemistry, fine chemicals and petrochemicals.

The main application varieties of molecular sieve are 3A, 4A, 5A, 13X and modified products with the above as the matrix.

3A molecular sieve use: drying of various liquids (such as ethanol); drying of air; drying of refrigerants; drying of natural gas and methane gas; Drying of unsaturated hydrocarbons and cracking gas, ethylene, acetylene, propylene, butadiene.

4A molecular sieve use: deep drying of gases and liquids such as air, natural gas, alkanes, refrigerants, etc.; Preparation and purification of argon; static drying of pharmaceutical packaging, electronic components and perishable substances; As a dehydrating agent in paints, fuels, coatings.

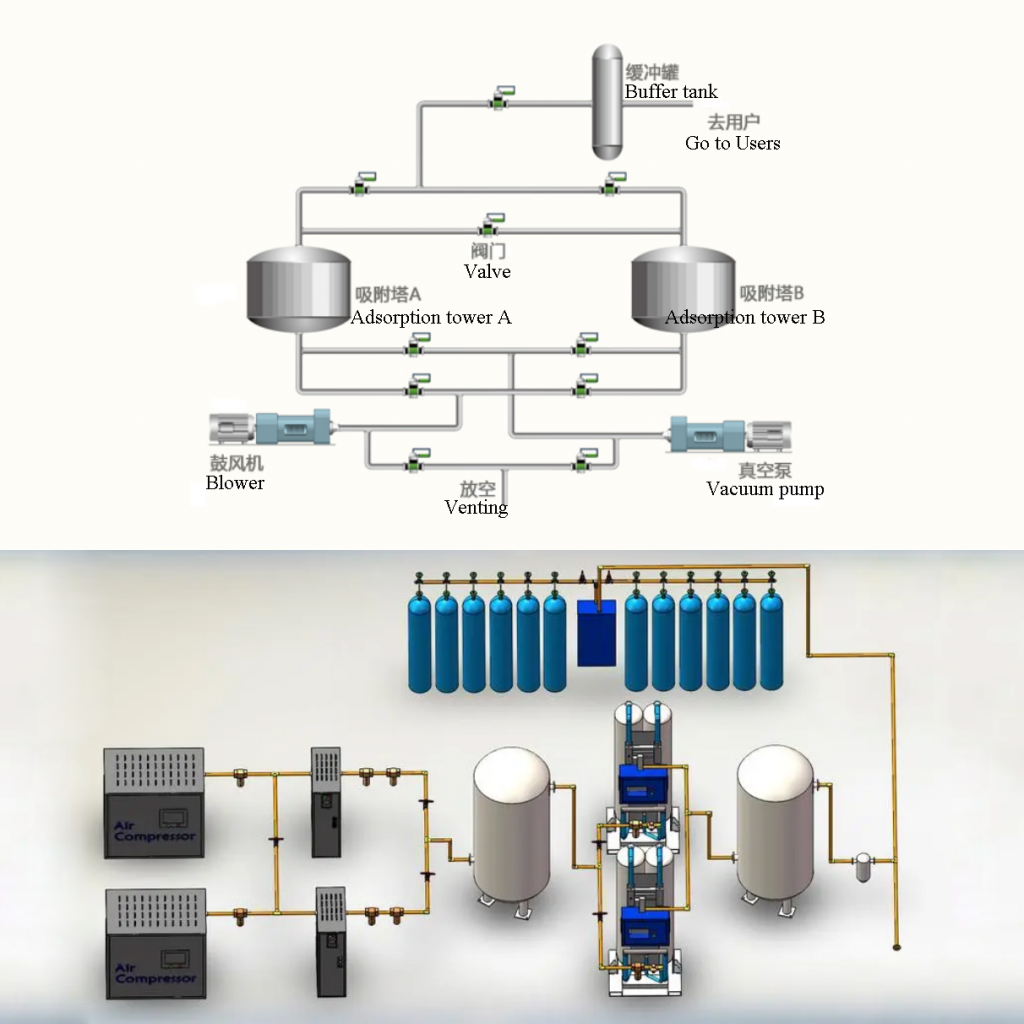

5A molecular sieve use: pressure swing adsorption; Air purification, dehydration and carbon dioxide.

13X molecular sieve use: gas purification in air separation device, removal of water and carbon dioxide; drying and desulfurization of natural gas, liquefied petroleum gas, liquid hydrocarbons; General gas deep drying.

Modified zeolite can be used as a catalyst and adsorbent for organic reactions.

Processing technology: using existing raw materials such as aluminosilicate ore or coal gangue, it is processed by crushing, molding (granulation or extrusion), high temperature sintering, soaking for a certain time with inorganic aqueous solutions such as sodium hydroxide, potassium hydroxide or calcium chloride at a certain temperature, and then washing, filtering, crushing, molding, health preservation, drying and activation processes.