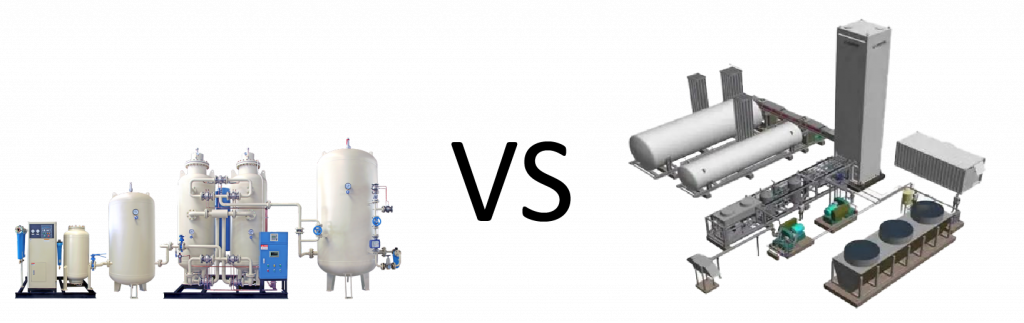

VPSA (low pressure adsorption vacuum desorption) oxygen production is another “variant” of PSA oxygen production, their oxygen production principle is almost the same, are the use of molecular sieve on different gas molecules “adsorption” ability to separate the gas mixture, but PSA oxygen production is through pressure adsorption, atmospheric pressure desorption to separate oxygen, VPSA oxygen generator is to adsorb saturated molecular sieve under vacuum conditions to desorption.

Although, both use air as raw materials, and the principle of oxygen production is similar. But in closer comparison, there are still the following differences;

- VPSA oxygen generator uses a blower to obtain raw material air and pressurize, while PSA oxygen generator uses an air compressor to supply air.

- In the selection of the core component – zeolite molecular sieve, PSA oxygen generator uses sodium molecular sieve, and VPSA oxygen generator uses lithium molecular sieve.

- The adsorption pressure of PSA oxygen generator is usually 0.6~0.8Mpa, and the adsorption pressure of VPSA oxygen generator is 0.05Mpa.

- PSA stand-alone gas production can reach 200~300Nm/h, VPSA stand-alone gas production can reach 7500~9000Nm/h.

- Compared with PSA, VPSA has low energy consumption (electricity consumption per square of oxygen is ≤0.5 kW), which is more environmentally friendly and green.

Although the VPSA oxygen generator has a large amount of oxygen in a single mechanism, its disadvantage is that the system equipment is relatively complex, the equipment volume is also large (still smaller than the cryogenic device), and the supporting common engineering conditions are more required, which will occupy a large space and cannot be made into oxygen equipment in the form of containers. On-site installation, commissioning, from this point alone. PSA still has certain advantages.