| 500 m³/h high purity nitrogen equipment Comparison table of air separation equipment and pressure swing adsorption nitrogen production | ||||

|---|---|---|---|---|

| number | Comparison items | Cryogenic method (air separation plant) | PSA(Pressure swing adsorption nitrogen production) | |

| 1 | cost of investment | 1. Basically equal 2. It can produce liquid nitrogen as a backup gas source. |

1. equal 2. Select imported molecular sieve and need to add carbon or hydrodeoxidation. |

|

| 2 | Startup time | The first 15 hours vary according to the length of downtime during operation. | ~40 minutes to 1 hour Fast boot time. | |

| 4 | Product gas quality | products with purity | 1.≥99.9995%(Oxygen content≤3ppm)And sustainably。 | 1. Enterprises that achieve ≥ 99.9995% purity in one step, there are currently no cases in China. 2. Only 99.9% purity can be made first, and then carburized deoxidation or hydrodeoxidation can be added, so the operation greatly increases the operating cost, and the purity of the product gas will decrease with the activity and decrease of molecular sieve. |

| Product cleanliness (at atmospheric dew point) | -70℃ over and above | -45℃ | ||

| 1. Nitrogen is dust-free 2. After the adsorption of the purifier and the rectification of the fractionation column, the nitrogen does not contain trace gases, such as carbon monoxide, carbon dioxide, argon and other trace gases. |

1. Nitrogen entrainment with a small amount of dust 2. The molecular sieve only adsorbs oxygen, and the trace gas in the nitrogen cannot be removed. |

|||

| 5 | Energy consumption (shaft power) 500 m³/h of high-purity nitrogen | ~165KW/h High extraction rate | ~215KW/h High purity nitrogen extraction rate is low | |

| 6 | operation | 1) Low cost. 2) It can be operated for a long time or intermittently. 3) After parking in the middle, the re-start time is shorter than the first start-up time, but it is still longer than the PSA. 4) Reliable and stable operation, automatic valve switching every 8 hours. 5) Air-nitrogen ratio: 3:1. |

1) High cost (due to the higher replacement cost of molecular sieve, especially carbon molecular sieve). 2) It can be operated for a long time or intermittently. 3) After parking in the middle, the re-start time is shorter. 4) It is easy to fail during operation, and the automatic valve is switched once in 1 minute. 5) Empty nitrogen ratio: 4.2:1 6) Long-term consumption of refined carbon or need to be equipped with hydrogen production devices |

|

| 6 | operating staff | 1 When operating normally, it only needs to be switched every 8 hours (Because the valve is switched every 8 hours). 2. The flow, pressure and purity of the product gas are reserved for ports, and the supply and demand side is connected to the DCS system, which can realize online monitoring and operation records. |

Inspection is required every hour (because the valve moves once every minute, it is too frequent and prone to failure) | |

| 8 | service life | The service life of the fractionation column can be as long as more than 20 years | The adsorber has a short service life of up to 10 years | |

| 9 | Equipment footprint | ~100 ㎡ | ~80㎡ | |

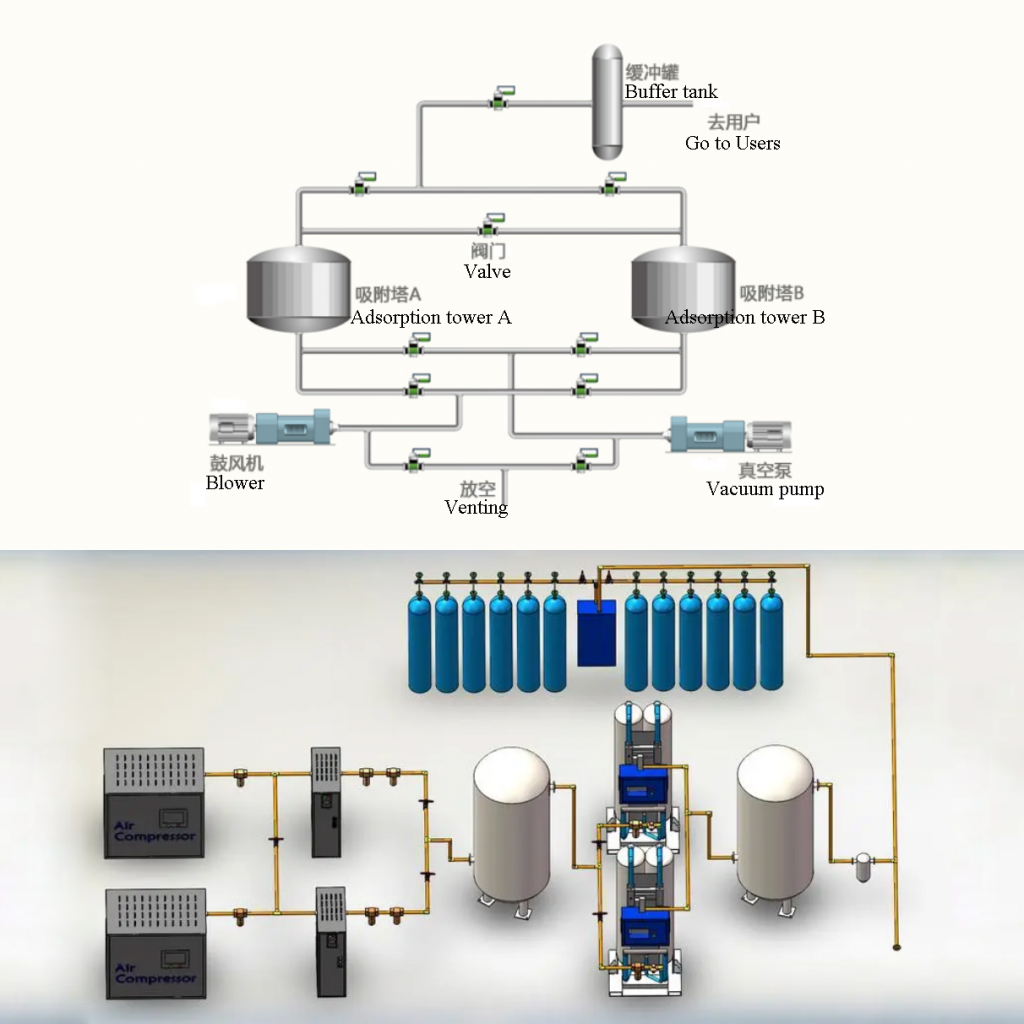

The Difference Between PSA And VPSA

Although, both use air as raw materials, and the principle of oxygen production is similar....