Oxygen supply to hospitals has always been a concern for hospitals. In particular, the choice of which oxygen as a medical oxygen source is very careful and important to the leaders of the country and the hospital.

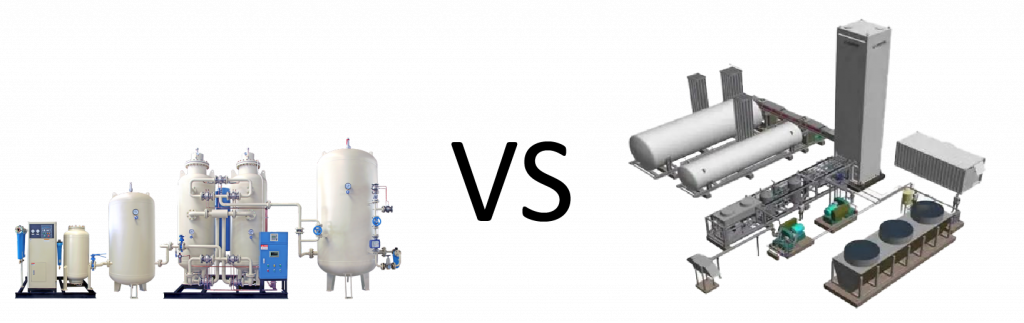

For many years, the protagonist of the medical oxygen stage is the medical oxygen prepared by the cryogenic [low temperature] method, which is impossible to install in hospitals due to the huge equipment, complex operation, high power, high noise, high pressure, high safety requirements, and long start-up time. Therefore, it is necessary to fill the medical oxygen [compressed to 13-15Mpa] in a cylinder, transport it to the hospital, and then card it in the secondary decompression of the bus to about 0.5Mpa and send it to the ward through the medical oxygen pipeline for the patient. It should be noted that in recent years, some hospitals have purchased and installed cryogenic liquid storage tanks [liquid oxygen tank] with a vaporizer to vaporize liquid oxygen [-170 °C] into gaseous oxygen and supply oxygen through pipelines, and the source of liquid oxygen is taken from the upper condensation evaporator of the cryogenic air separation equipment, which is still a cryogenic equipment product. It is transported by cryogenic liquid tank truck and filled to the hospital’s liquid oxygen tank through a cryogenic liquid pump, and then vaporized through the vaporizer and then enters the oxygen supply pipeline.

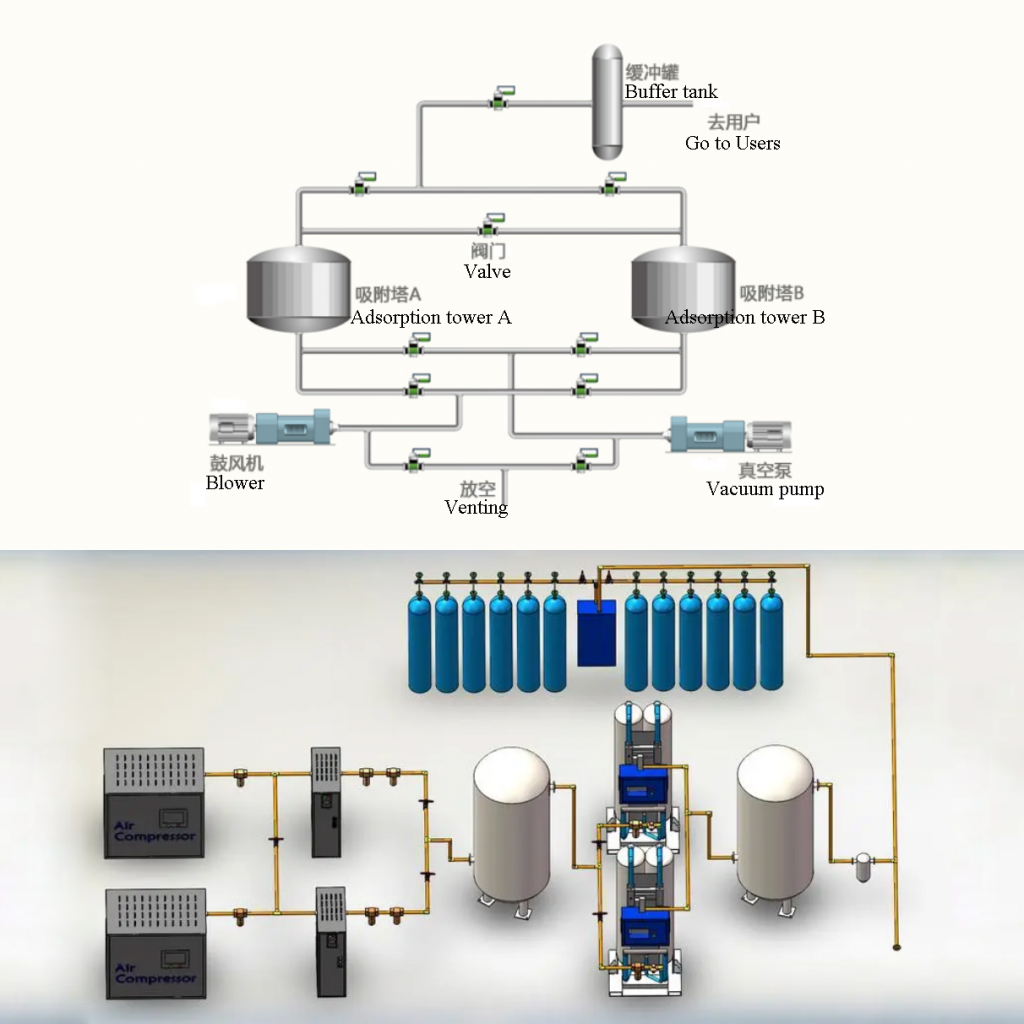

PSA medical oxygen generator that enters the hospital at the same time as the cryogenic liquid tank is a physical method of producing oxygen at room temperature under low pressure [0.6Mpa], which occupies a small area, small power preparation, short start-up time, simple operation [fully automatic], and a fairly safe air separation method. It is particularly suitable for piped oxygen supply.

Below, we compare the two oxygen sources of cryogenic liquid tank for medical oxygen and PSA medical oxygen generator for medical oxygen.

Economic comparison:

1.The following cryogenic liquid tank is referred to as the tank: at present, the market price of liquid oxygen is on average 1300 yuan m3, the vaporization ratio is calculated by 800, taking the bottle as the comparison unit, each bottle contains 5Nm3 oxygen, then the price of each bottle of oxygen is 8.1 yuan plus heat transfer evaporation pressure leakage, and the price of each bottle of oxygen is about 10 yuan If the tank is more than two years, the leakage rate can be as high as 30%, and it is necessary to constantly vacuum to avoid the strong use of

2.PSA oxygen generator hereinafter referred to as the machine: the medical oxygen mono-oxygen power consumption of the machine is 1.20/m3O2, equivalent to 6 degrees per bottle, the electricity price is 0.8 yuan, and each bottle of oxygen is 6 yuan slightly cheaper than liquid oxygen By comparison, it can be seen that the economy of the two methods is close, and the machine supply is slightly better than the trough supply. However, because the machine supply mode is connected with the pipeline as a system, the wave behind the river pushes the wave ahead, and the produced oxygen can be fully utilized. The tank oxygen leakage is absolute and inevitable, and there must be excess pressure during use, so the tank oxygen can not be fully utilized. In fact, the economy of the machine supply is better than that of the tank supply. The maintenance costs of the two kinds of machine supply should be close To choose which scheme, the user unit must make a detailed comprehensive budget

Comparison of floor space:

- The tank itself filler covers an area of at least 15 square meters [including operation space], the safety space needs to be at least 180 square meters [hard requirements], and the total area needs to be more than 200 square meters.

- The machine itself covers an area of only 3-5 square meters, plus the oxygen storage tank and operating space of 20 square meters is enough [of course, a little larger will make the image good].

It is clear: the footprint of the machine is only one-tenth of the slot.

Comparison of operational techniques:

- The entry of oxygen in the tank needs to be sent by a special cryogenic liquid tanker, and the liquid oxygen is pumped into the tank through the low-temperature adiabatic pipeline with a cryogenic liquid pump, and the liquid oxygen in the tank is vaporized through the vaporizer and enters the oxygen supply pipeline. Liquid oxygen vaporization is to boost, and the boost amplitude is related to the output flow and design, as well as the ambient temperature. If the insulation in the tank falls, the pressure in the tank rises only by relying on the automatic pressure relief control of the safety valve, so to operate the system safely, the technology is very strong, and the operator must have professional knowledge and professional ability to obtain professional operation qualifications.

- The machine is oxygen-producing equipment, low pressure automatic operation, no special operation, only need maintenance, make records, general mechanical repair ability can be used and open the equipment

Security Comparison:

- The tank is double-layered, and the sandwich is filled with thermal insulation material [perlite or magnesium carbonate, magnesium carbonate is not as good as perlite], and then pumped into a vacuum. The tank is to store liquid oxygen at minus 170 degrees at room temperature. The vaporization ratio of liquid oxygen is 1:800 [or 850], which means that if one cubic meter of liquid oxygen vaporizes instantly, the volume will rise to more than 800 cubic meters! Its swelling pressure is enough to crush the groove powder! At the same time, at ultra-low temperatures, everything including steel becomes brittle to the point of vulnerability! In addition, the strong oxidation of liquid oxygen, once leaked, can make people frostbite and deoxygenate the human body, with strong corrosiveness, the consequences are very serious. Its strong combustion performance increases the burden of fire fighting. The thermal insulation performance of the tank can generally reach more than two years, once the vacuum degree drops or the insulation material is damp, its insulation is threatened, and the user has to increase the vacuum pump to continuously vacuum the tank interlayer to maintain its thermal insulation performance.

3.The machine works at low pressure, and it changes from zero pressure to the highest pressure [0-0.6Mpa] cycle, and the cycle is very short, only tens of seconds, that is, when the danger does not appear pressure before the pressure drops to normal pressure. At the same time, the gas source is the air compressor, the air compressor has a well-adjusted safety valve, once the pressure exceeds 0.7Mpa, the valve automatically opens; The air compressor is also equipped with a pressure switch, when the pressure reaches its set value, the air compressor automatically stops and automatically unloads, ensuring the safety of the system from the source. The tanks configured by the machine are equipped with a calibrated safety valve, and a pressure relief device controlled by an industrial microcomputer is also provided underneath. It can be said that the safety of the machine is fully protected from the source to the entire system, and its security is quite high.

Comparison of flexibilities:

- The tank must have a professional manufacturer’s low-temperature tank car to send liquid oxygen to use, its use must rely on outsourcing, there is no autonomy in oxygen use.

- There is no such problem as the machine. When oxygen is needed, it automatically starts, immediately produces oxygen, and automatically adjusts within the design flow range. It realizes the independent oxygen supply of the hospital, which is not constrained by man-made, weather, traffic and other factors.

Transparency comparison:

- The tank oxygen is specially transported by the factory, and the quality of the liquid oxygen such as purity, whether it is contaminated, whether it is medical oxygen [liquid oxygen is not necessarily medical oxygen] and other hospital parties do not know, and there is no condition to directly obtain the parameters, can only default to the factory’s promise and certificate.

- The machine does not have this problem, and the purity of medical oxygen can be seen intuitively; As long as the purity reaches the standard, the water content must be qualified, otherwise the purity cannot reach the standard [this is determined by the production process of the machine]

Service life comparison:

- The vacuum of the tank is time-sensitive. Many units using the slot have such and such problems after using the slot for two years, and some have been discontinued in one or two years [there are many examples, such as the 153 Hospital of the Zhengzhou People’s Liberation Army], and there are many troubles in the later stage.

- The life of the machine is mainly determined by the molecular sieve, its life should be more than ten years, we guarantee the quality for users for five years, it can be said that the life of the machine is much longer than the tank.

Comparison of policy restrictions:

- The installation of the slot is very demanding, and it must be installed by a professional team. The location of the trough has extremely high requirements for the surrounding environment, no less than the construction of liquefied gas filling and irrigation stations, and no buildings are allowed within a radius of 15 meters, let alone in residential areas.

- The safety requirements of the machine are much lower, and it can be installed downstairs, in the building, even on the roof, of course, it can also be installed in the bungalow.

In summary, it can be shown that the use of PSA medical oxygen generator is better than that of cryogenic liquid storage tank. Especially in today’s urban land shortage and every inch of land, medical oxygen concentrators show her superiority.